Choosing between air-cooled and water-cooled machines depends on your specific needs and environment. Air cooling is cost-effective, easier to install, and suits smaller or portable applications, but it may be noisier and less efficient in high-heat conditions. Water cooling offers superior temperature control, better heat management, and is ideal for high-performance or industrial setups, though it comes with higher costs and maintenance. To discover which system suits your requirements best, consider the details ahead.

Key Takeaways

- Choose water cooling for high heat output, precise temperature control, and stability in large-scale or humid environments.

- Opt for air cooling if space, water access, or budget constraints favor easier installation and maintenance.

- Consider water cooling for better thermal insulation and cooling efficiency in demanding industrial applications.

- Use air cooling for portable, temporary, or low to moderate cooling needs with simpler setup.

- Evaluate environmental factors like climate and water availability to determine the most suitable cooling method.

Understanding the Fundamentals of Cooling Systems

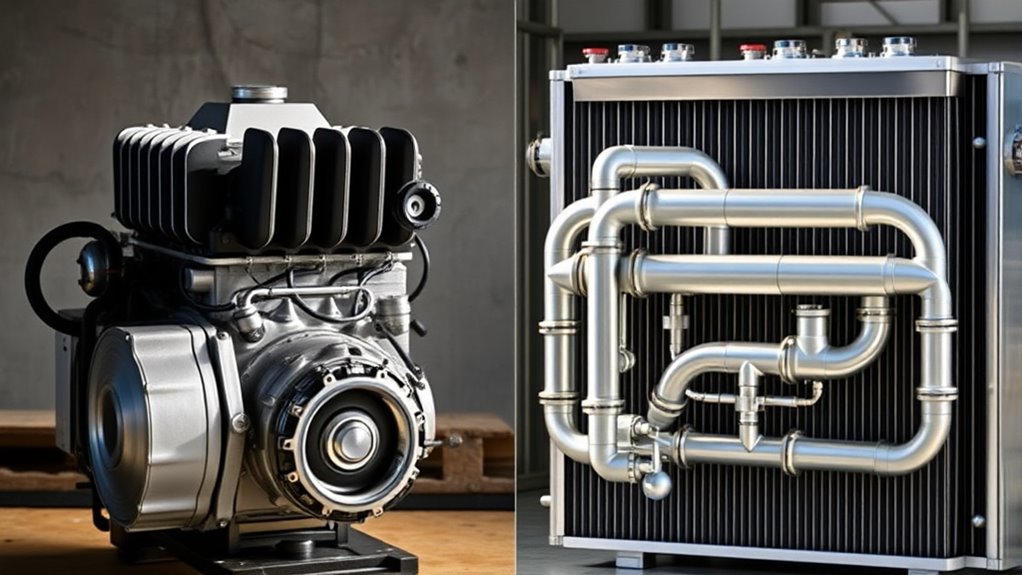

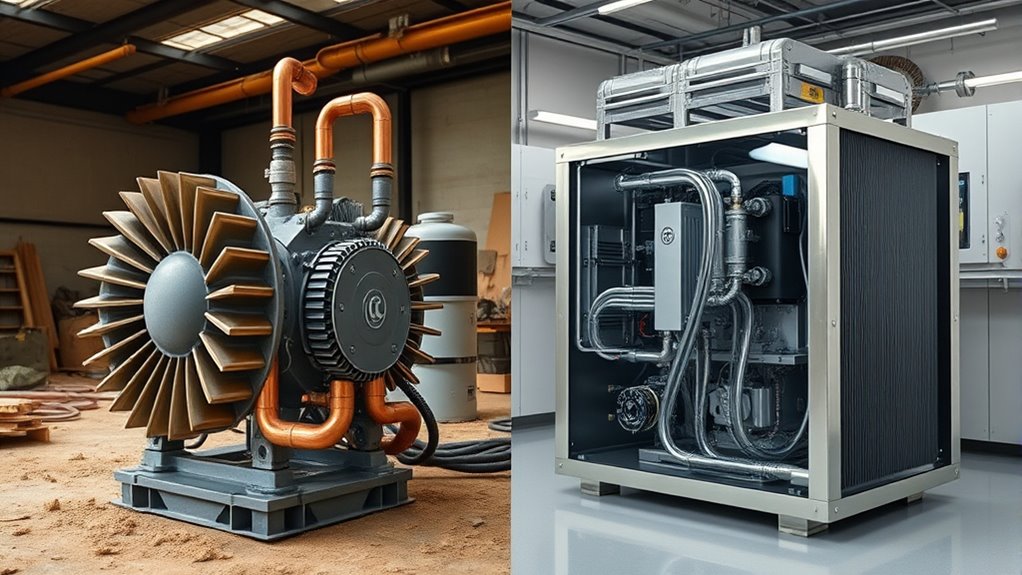

Understanding how cooling systems work is essential to grasp the differences between air-cooled and water-cooled machines. Cooling technology focuses on removing excess heat to maintain ideal performance. In thermal regulation, heat is transferred away from critical components to prevent overheating. Air-cooled systems rely on fans and heat sinks to dissipate heat into the surrounding air, making them simpler and more accessible. Water-cooled systems use liquid coolant circulated through pipes to carry heat away more efficiently, especially in high-performance settings. By understanding these fundamentals, you can better assess which cooling approach aligns with your needs. Both methods aim to manage temperature effectively, but they do so using distinct processes that impact efficiency, maintenance, and suitability for different applications. Additionally, knowledge of family dynamics can influence how one perceives the importance of reliable cooling systems in personal and professional environments.

Advantages and Disadvantages of Air-Cooling

Air cooling offers cost efficiency benefits since it requires less upfront investment and fewer parts. However, it can generate more noise and needs regular maintenance to stay effective. Considering these factors helps you decide if air cooling suits your needs. Essential oils for respiratory health suggest that proper ventilation and maintenance can enhance overall system performance and air quality.

Cost Efficiency Benefits

Choosing an air-cooled system often proves more cost-effective upfront because it eliminates the need for complex plumbing and liquid components. This reduces your initial investment, making it more accessible if you’re on a tight budget. Air cooling systems typically have lower installation costs and fewer parts that wear out, which can translate into long-term savings. While they may consume slightly more energy than water-cooled options, the difference is often minimal, and the ease of maintenance helps keep operational costs down. Over time, the simplicity of air-cooled systems can lead to better energy savings and reduced downtime. Additionally, the high water content in vegetables used for juicing supports hydration and overall health, which is an advantage of choosing fresh produce for juices. Overall, if you’re prioritizing initial investment and straightforward maintenance, air-cooled machines offer notable cost efficiency benefits.

Noise and Maintenance

While air-cooled systems generally generate less noise than water-cooled options, they can still produce noticeable sound during operation, especially in high-performance applications. The noise levels tend to be moderate, but in quiet environments, it might be distracting. Maintenance frequency for air-cooled machines is typically lower since they have fewer components like pumps or water reservoirs to service. However, filters and fans require regular cleaning to maintain ideal performance. The table below compares the advantages and disadvantages of air-cooling related to noise and maintenance: Forsale 100

| Aspect | Details |

|---|---|

| Noise levels | Generally lower but can be noticeable during high load |

| Maintenance frequency | Usually lower, mainly filter and fan cleaning |

| Disadvantages | Noise can still be disruptive in quiet settings |

| Advantages | Less complex, fewer parts to maintain |

| Overall impact | Suitable for environments needing quieter operation |

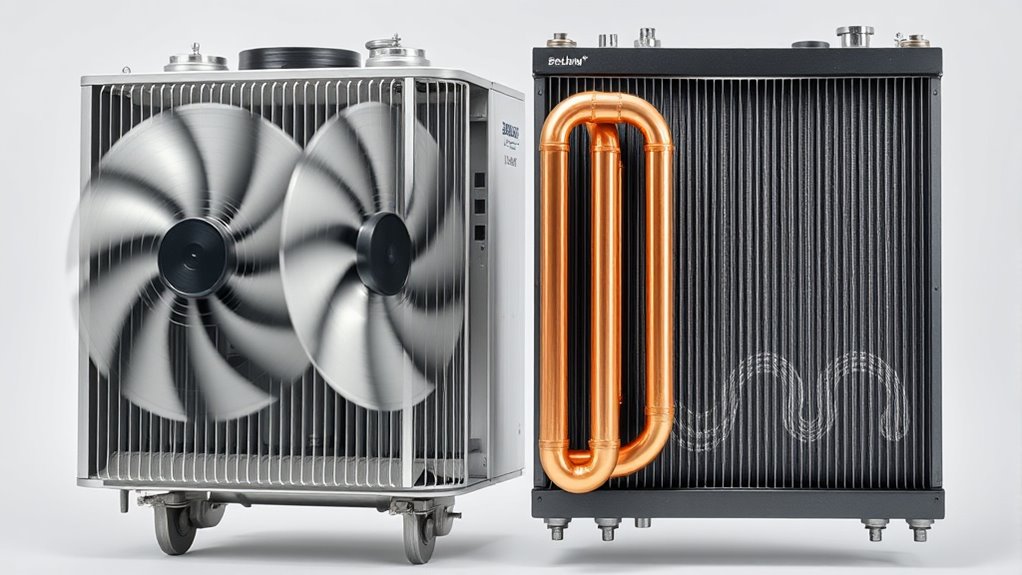

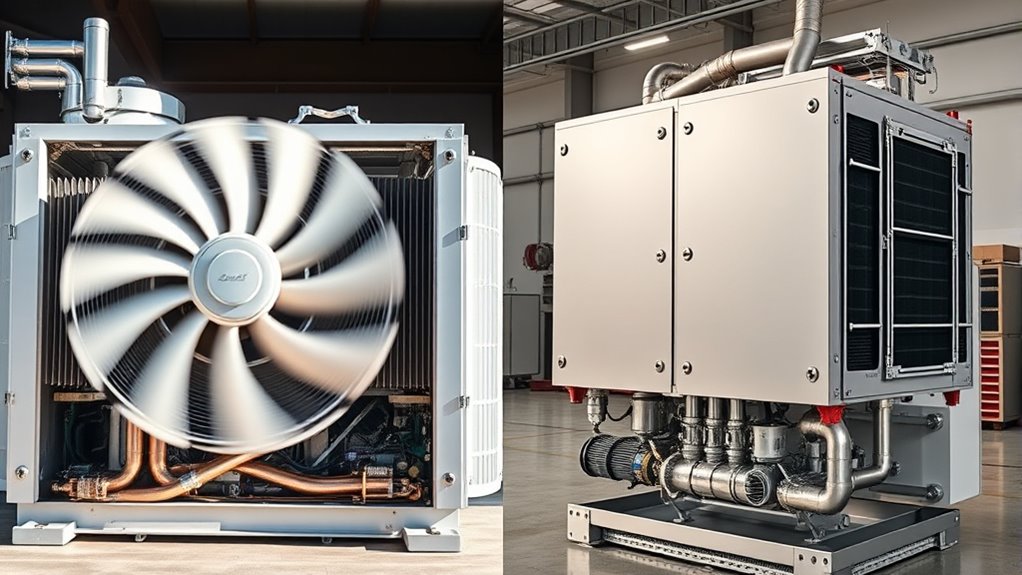

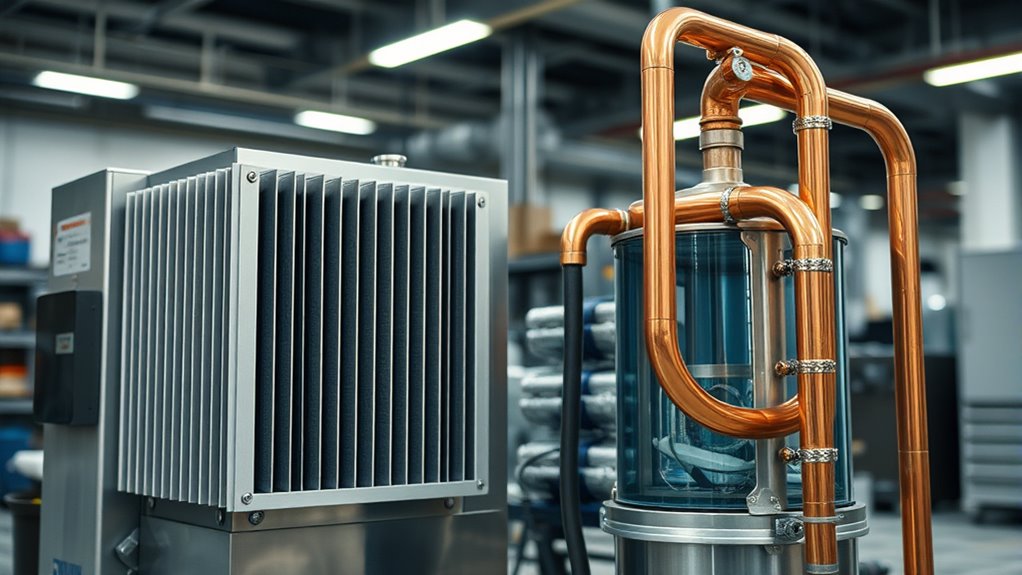

Benefits and Limitations of Water-Cooling

Water-cooling offers significant benefits, especially in managing heat more efficiently than air-based systems. It provides superior thermal regulation, helping your machine stay within ideal temperature ranges during heavy use. This precise temperature control can extend system durability, reducing wear and tear on components. Additionally, AI safety measures are crucial to ensure reliable operation and prevent potential failures. However, water-cooling also has limitations. It’s more complex to install and maintain, requiring additional parts like pumps, radiators, and coolant. There’s a risk of leaks, which can damage sensitive components if not properly managed. Water-cooling systems are generally more expensive upfront and can be less convenient for those seeking a simple setup. Despite these drawbacks, if you need high performance and better thermal regulation, water-cooled systems can offer long-term benefits with proper upkeep.

Cost Analysis and Maintenance Considerations

When evaluating water-cooling systems, cost and maintenance are crucial factors to take into account. A thorough cost comparison reveals that water-cooled machines often have higher initial expenses due to complex components like pumps and radiators. Maintenance frequency also tends to be greater; water systems require regular checks for leaks, corrosion, and coolant levels. Additionally, the use of quality materials in these systems can influence their durability and longevity. Conversely, air-cooled machines usually demand less maintenance, with fewer parts that can fail or need replacement. While water cooling might incur higher setup costs, its efficiency can reduce operational expenses over time. However, you’ll need to weigh these ongoing maintenance demands against the initial investment. Ultimately, your decision should consider your budget, willingness to perform routine upkeep, and the long-term costs associated with each cooling method.

Suitability for Different Applications and Environments

You need to contemplate the environmental conditions where the machine will operate to choose the right cooling system. Air-cooled options work well in dry, moderate climates, while water-cooled systems excel in high-temperature or humid settings. Think about your application type, as some machines demand more precise cooling methods for ideal performance. Additionally, consider the crochet styles for locs to ensure your equipment supports the desired styling flexibility and protection.

Environmental Conditions Compatibility

Environmental conditions profoundly influence the suitability of air-cooled and water-cooled machines for various applications. You need to take into account factors like ambient temperature, humidity, and available space when choosing a cooling method. For example:

- Hot climates may challenge air-cooled units due to lower thermal conductivity and less effective heat dissipation.

- Water-cooled systems perform better where ambient temperatures are high, as they can maintain ideal operating temperatures.

- If water quality is poor or water availability is limited, air-cooled machines become more practical.

- Refrigerant choices impact environmental compatibility, with some refrigerants better suited for specific conditions or regulations.

- Regular maintenance and monitoring of glycolic acid products can help optimize cooling efficiency and prevent system issues. Glycolic acid products are often used to maintain optimal temperatures and protect against corrosion in cooling systems.

Matching your environment with the cooling system ensures efficiency, longevity, and compliance with environmental standards.

Application Type Suitability

Choosing the right cooling system depends heavily on the specific application and environment. If you need high industrial efficiency for continuous operations, water-cooled machines excel due to their superior heat management. They’re ideal for large-scale industrial settings where stability is vital. Conversely, if portability matters, air-cooled systems offer a portable design that’s easier to install and maintain, making them suitable for temporary or mobile applications. For environments with limited space or where water access is restricted, air cooling provides a practical solution. Consider your application’s heat output, environmental constraints, and the significance of mobility. Additionally, understanding the different beach destinations can help you better appreciate diverse environments if your application involves outdoor or coastal settings. Matching your needs with the appropriate cooling method ensures peak performance, longevity, and cost-effectiveness, helping you choose a system that aligns perfectly with your operational demands.

Making the Right Choice for Your Needs

Deciding between air-cooled and water-cooled machines depends on your specific needs and operational environment. To make the right choice, consider these factors:

- Humidity control: Water-cooled systems often excel at maintaining stable humidity levels, essential for sensitive processes.

- Thermal insulation: Water cooling provides better thermal insulation, preventing heat transfer to surrounding equipment.

- Space constraints: Air-cooled machines typically require less space and simpler setup.

- Maintenance needs: Water systems may need more maintenance due to potential leaks, corrosion, or bacterial growth.

- Additionally, understanding the cooling efficiency of each system can help optimize performance and energy consumption.

Evaluate your environment’s cooling demands, space, and maintenance capabilities. If precise humidity control and thermal insulation matter most, water cooling might be better. For ease of use and space efficiency, air cooling could be ideal.

Frequently Asked Questions

How Long Do Air-Cooled and Water-Cooled Systems Typically Last?

You might wonder how long air-cooled and water-cooled systems last. Typically, air-cooled units last around 10-15 years, while water-cooled systems can last 15-20 years with proper maintenance. Keep in mind, maintenance costs are usually higher for water-cooled systems due to their complexity. Noise levels also differ; air-cooled systems tend to be noisier, whereas water-cooled units operate more quietly, which could influence your choice.

Are There Any Environmental Impacts Associated With Each Cooling Method?

You might wonder about the environmental impacts of cooling methods. Air-cooled systems generally have a smaller environmental footprint since they use less water, promoting resource sustainability. Water-cooled machines, however, can consume significant water resources and may require chemicals for cooling, impacting local ecosystems. By choosing an air-cooled system, you reduce water use and support resource sustainability, helping lessen your overall environmental impact.

Can Hybrid Cooling Systems Combine Air and Water Cooling?

Imagine blending two powerful forces—hybrid cooling systems do just that, combining air and water cooling for superior cooling integration. This hybrid efficiency allows you to tailor cooling solutions to your needs, balancing performance and energy use. By integrating both methods, you gain flexibility, reduce environmental impact, and optimize system longevity. So yes, hybrid systems can effectively merge air and water cooling, offering a versatile, efficient approach to managing heat.

What Are Common Troubleshooting Issues for Each Cooling Type?

You should perform regular cooling system maintenance to prevent issues. For air-cooled systems, check for dust buildup and ensure fans are working properly. Water-cooled systems often face leaks, clogged radiators, or pump failures. Troubleshooting procedures include inspecting for leaks, cleaning components, and verifying fluid flow. Addressing these common issues promptly helps keep your cooling system efficient and extends its lifespan.

How Do Cooling System Choices Affect Overall Machine Performance?

Your cooling system choice directly impacts your machine’s thermal efficiency and maintenance costs. An efficient system keeps temperatures ideal, boosting performance and reducing wear. Water-cooled setups often enhance thermal efficiency but may incur higher maintenance costs due to potential leaks and component upkeep. Air-cooled systems are simpler and cheaper to maintain but might struggle with thermal efficiency during heavy use. Consider your operational demands to balance performance and maintenance expenses.

Conclusion

Choosing between air and water cooling is like selecting the right vessel for a voyage. Air cooling is your sturdy, reliable boat—simple and low-maintenance, perfect for calm waters. Water cooling is like a sleek speedboat—faster and more efficient, but requires more care. Consider your journey’s demands carefully. With the right choice, you’ll navigate your thermal challenges smoothly, ensuring your machine sails efficiently and safely through any environment.