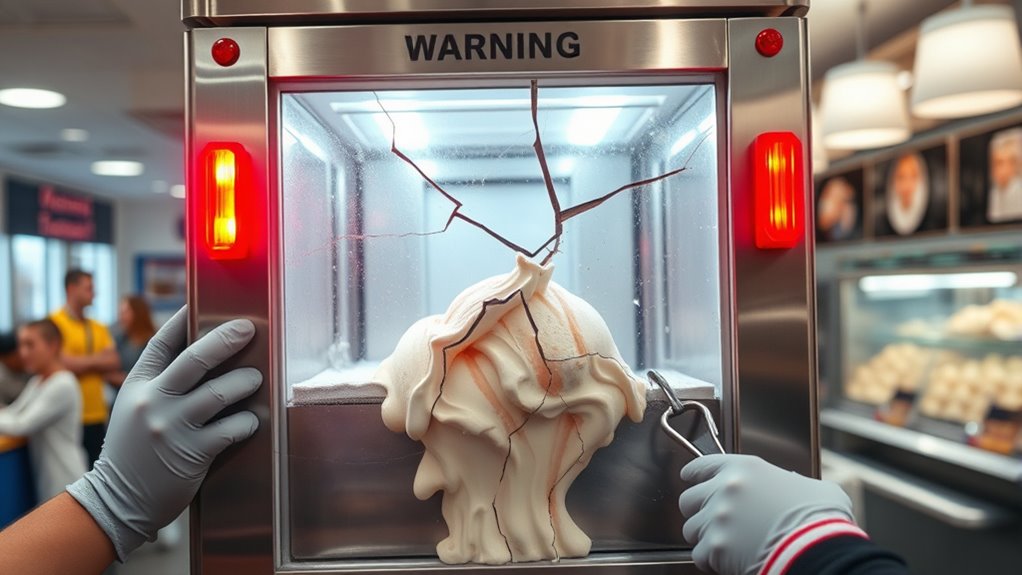

If your ice cream machine suddenly malfunctions, immediately turn it off and unplug it to prevent further damage. Check for obvious issues like jammed parts, electrical faults, or buildup. Follow manufacturer instructions for cleaning and troubleshooting. If the problem persists, don’t attempt complex repairs yourself—seek professional help promptly to avoid costly damage. Keep going to learn more about quick fixes and safety steps to get your machine back in action fast.

Key Takeaways

- Power down and unplug the machine immediately to prevent electrical hazards or further damage.

- Check for obvious blockages, jams, or leaks and clear any debris or residue.

- Inspect wiring and electrical components for damage or loose connections.

- Consult the manufacturer’s troubleshooting guide for specific error codes or issues.

- Contact professional repair services promptly to diagnose and fix complex problems safely.

Assess the Situation and Identify the Issue

When your ice cream machine stops working unexpectedly, the first step is to assess the situation carefully. Check for obvious issues like power supply problems or jammed parts. Follow some basic maintenance tips to see if anything is visibly out of place or dirty. Clean the machine’s components according to the cleaning procedures recommended by the manufacturer, as buildup or residue can cause malfunctions. Listen for unusual noises or vibrations, and observe if the display panel shows error codes. Identifying whether the problem stems from a mechanical failure, electrical issue, or blockage helps you determine the next steps. Taking these initial assessments guarantees you understand what’s wrong before attempting any repairs, reducing the risk of further damage or injury. Additionally, understanding common mechanical failures can help you troubleshoot more effectively.

Power Down and Disconnect Safely

Before attempting any repairs or maintenance, you should power down and disconnect the ice cream machine to guarantee safety. Turning off the machine prevents electrical shocks and avoids further damage. Once powered down, unplug it from the power source to confirm it’s completely disconnected. This step is essential before performing cleaning procedures or inspecting parts. Check that the machine is cool and safe to handle. If you need spare parts, verify their availability beforehand to streamline repairs. Disconnecting safely also helps prevent accidental activation during maintenance, reducing risks. Always follow manufacturer instructions for power down procedures. Making sure the machine is fully unplugged and de-energized minimizes hazards, keeps you safe, and prepares the equipment for any necessary cleaning or part replacement. Additionally, inspecting the electrical components ensures there are no signs of damage or wear that could cause hazards during servicing.

Check for Common Mechanical or Electrical Problems

After ensuring the machine is completely powered off and unplugged, inspect it for common mechanical and electrical issues that could be causing problems. Look for loose wiring, damaged cords, or burnt components, which often indicate electrical issues. For mechanical problems, check for jammed parts, worn belts, or frozen components. Regular cleaning tips and adhering to your maintenance schedule help prevent these issues. Use the table below to guide your inspection:

| Issue | Possible Cause | Action |

|---|---|---|

| Machine not starting | Electrical connection fault | Reconnect or replace wiring |

| Unusual noises | Worn or loose parts | Tighten or replace parts |

| Ice buildup or freezing | Dirty components, poor maintenance | Clean thoroughly, check schedule |

| Compressor not working | Electrical or mechanical fault | Call for professional help |

| Excessive vibrations | Misaligned parts | Realign components |

Consistent maintenance practices can also help identify potential issues early and keep your ice cream machine running smoothly.

Stay proactive with regular maintenance and cleaning tips to avoid emergencies.

Consult the Manufacturer’s Troubleshooting Guide

Consulting the manufacturer’s troubleshooting guide is a crucial step when diagnosing issues with your ice cream machine. This guide provides specific troubleshooting steps tailored to your model, helping you identify causes that affect ice cream quality. Review the guide thoroughly to check for common problems, such as inconsistent texture or freezing issues. It often includes tips on calibration, cleaning, and parts replacement, ensuring your maintenance schedule stays on track. Following these instructions can quickly pinpoint whether the issue stems from misalignment, worn parts, or electrical faults. Using the manufacturer’s guide saves you time and prevents unnecessary repairs. It also helps you understand how to maintain ideal performance, ensuring your ice cream continues to meet high-quality standards. Regular tuning and maintenance based on the guide can extend the lifespan of your machine and improve overall efficiency.

Contact Professional Repair Services Immediately

When your ice cream machine malfunctions beyond simple troubleshooting, contacting professional repair services is essential. Expert technicians can diagnose issues quickly, perform routine maintenance, and guarantee your machine works efficiently again. Prompt repair minimizes downtime and prevents further damage. Reach out to customer support to schedule an inspection or get advice on troubleshooting. Here’s a quick guide to understanding service options:

| Service Type | Benefits | When to Use |

|---|---|---|

| Routine Maintenance | Prevents breakdowns | Regularly scheduled visits |

| Emergency Repair | Fast resolution of urgent issues | Immediate action needed |

| Parts Replacement | Restores functionality | Worn or broken components |

| Troubleshooting Support | Expert advice | Diagnostic assistance |

| Customer Support | Personalized guidance | General inquiries |

Frequently Asked Questions

How Can I Prevent Future Ice Cream Machine Emergencies?

To prevent future emergencies, you need to prioritize preventative maintenance and staff training. Regularly inspect and clean the machine, checking for wear and tear, and follow the manufacturer’s maintenance schedule. Make certain your staff knows how to operate and troubleshoot the equipment properly. This proactive approach minimizes breakdowns, keeps your machine running smoothly, and reduces costly emergency repairs, ultimately guaranteeing uninterrupted service and satisfied customers.

What Safety Gear Should I Wear During Troubleshooting?

When troubleshooting an ice cream machine, you should wear protective gloves and safety goggles to guarantee your safety. Gloves protect your hands from sharp parts, hot surfaces, or chemical cleaning agents, while goggles shield your eyes from splashes or debris. Always prioritize safety gear to prevent injuries and ensure a smooth repair process. Remember, taking these precautions helps you work confidently and avoids potential accidents during maintenance.

Are There Any Temporary Fixes I Can Try Myself?

When considering DIY repair or troubleshooting tips, you might wonder if there are temporary fixes you can try yourself. Always guarantee safety first, then check for simple solutions like cleaning filters, inspecting for clogs, or resetting the machine. These quick troubleshooting tips can sometimes resolve minor issues temporarily. However, avoid complex repairs beyond your skill level, and call a professional if problems persist to prevent further damage.

How Long Should I Wait Before Calling a Professional?

You should wait about 30 minutes to an hour before calling a professional, depending on the issue. During this time, follow your maintenance checklist and try basic troubleshooting steps. If the problem persists or worsens, don’t hesitate to contact emergency contacts or a technician. Prompt action guarantees minimal downtime and prevents further damage, so act quickly but give it some time first to see if simple fixes work.

Can I Use the Machine if It Emits Unusual Noises?

Before using the machine if it emits unusual noises, pause and perform a quick inspection. Don’t ignore the noise; it could signal a serious problem. Conduct a noise diagnosis to identify potential issues and guarantee safety. If you’re unsure or notice strange sounds, it’s better to halt operations and call a professional. Prioritize safety over productivity to prevent costly damage or accidents. Always trust your instincts—pause, inspect, and proceed cautiously.

Conclusion

Knowing what to do can save your ice cream machine from costly damage. Did you know that nearly 60% of machine breakdowns could be prevented with quick troubleshooting? By evaluating the situation, shutting down safely, and consulting experts when needed, you can keep your machine running smoothly. Acting fast not only saves money but also ensures you don’t miss out on delicious treats. Stay prepared and handle emergencies promptly to enjoy perfect ice cream every time!