Keeping your ice cream machine in top shape is essential for your business. Regularly replacing seals and gaskets prevents leaks, while maintaining nozzles, evaporator coils, and the compressor ensures consistent quality and efficiency. Checking electrical components and cleaning the condenser reduces downtime. Staying on top of these critical parts boosts reliability, saves money, and keeps your customers happy. Want to learn how these simple steps can greatly improve your business? Keep going for more insights.

Key Takeaways

- Regularly replacing seals and gaskets prevents leaks, ensuring continuous operation and protecting your investment.

- Proper maintenance of nozzles and valves guarantees smooth flow and consistent servings, boosting customer satisfaction.

- Cleaning condenser coils enhances energy efficiency, reduces downtime, and extends the lifespan of your refrigeration system.

- Prompt electrical troubleshooting and electrical component upkeep prevent costly repairs and machine failures.

- Routine inspection and maintenance of the evaporator coils and auger parts maintain product quality and prevent costly breakdowns.

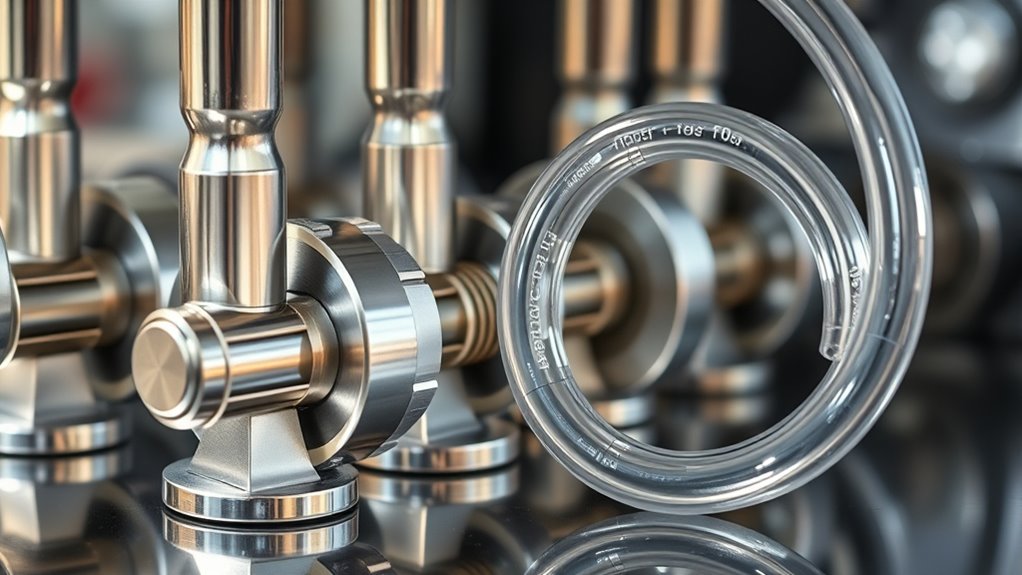

The Importance of Replacement Seals and Gaskets

Seals and gaskets play a vital role in keeping your ice cream machine functioning smoothly, as they prevent leaks and keep contaminants out. Regularly inspecting and replacing worn seals ensures your machine operates efficiently and maintains product quality. Establishing a consistent cleaning schedule is essential, as buildup or damage can compromise these parts’ effectiveness. Proper maintenance not only extends the lifespan of your seals and gaskets but also safeguards your warranty coverage, preventing issues that could void your warranty. Don’t overlook this small but crucial component; neglecting its condition can lead to costly repairs or downtime. By prioritizing routine checks and timely replacements, you protect your investment and keep your ice cream production running without interruption. Utilizing professional equipment for maintenance can further ensure high-quality performance and longevity.

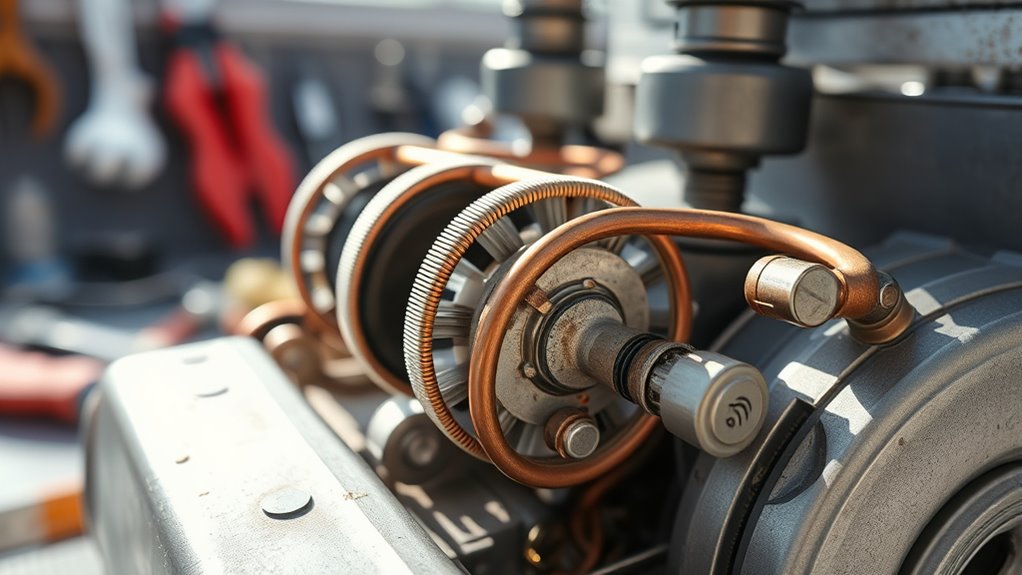

Troubleshooting and Replacing the Compressor

If your ice cream machine isn’t cooling properly, you might need to verify the compressor for issues. When replacing it, you’ll want to guarantee it’s installed correctly to avoid future problems. We’ll guide you through identifying compressor problems, swapping out the unit, and reassembling everything properly. Additionally, ensuring your filtering system is functioning well can prevent debris from damaging the compressor and other components.

Identifying Compressor Issues

Have you noticed your ice cream machine isn’t chilling properly or making strange noises? These signs often point to compressor issues. If the compressor isn’t functioning correctly, your machine can’t maintain the proper ice cream flavor or texture, frustrating your customers and hurting your customer service reputation. Listen for loud, rattling, or buzzing sounds, which may indicate a failing compressor. Check for overheating or leaks around the compressor unit. A sudden loss of cooling efficiency suggests an internal problem. Identifying these issues early can prevent further damage and ensure your machine runs smoothly. Regular maintenance checks can help catch compressor problems before they lead to total failure. Remember, addressing compressor problems promptly keeps your ice cream at its best, preserving flavor quality and keeping your customers happy.

Replacing the Compressor

When you notice persistent compressor issues like strange noises, overheating, or loss of cooling, replacing the compressor becomes necessary to restore proper function. You’ll want to follow these steps:

- Disconnect power and safely access the compressor, ensuring you keep the ice cream flavor intact.

- Drain refrigerant carefully, adhering to safety guidelines and environmental regulations.

- Remove the faulty compressor, inspecting connections and seals for damage.

- Install the new compressor securely, then recharge the system with refrigerant, checking for leaks.

- Regular maintenance and proper refrigerant handling can help prevent future compressor problems and extend the lifespan of your ice cream machine.

Throughout this process, prioritize excellent customer service by explaining delays to your customers and maintaining quality standards. Replacing the compressor might seem complex, but it’s essential to keep your ice cream machine running smoothly and your customers satisfied.

Ensuring Proper Reinstallation

To guarantee your compressor is properly reinstalled, you need to carefully verify that all connections are secure and free of leaks. Double-check refrigerant lines, electrical wiring, and mounting brackets. Proper cleaning procedures ensure no debris or moisture interfere with performance. Staff training plays a key role—make sure your team knows how to handle reinstallation steps precisely. Use this checklist to stay organized:

| Task | Tip |

|---|---|

| Inspect connections | Ensure tight, leak-free seals |

| Check electrical wiring | Confirm all wires are securely attached |

| Clean compressor area | Remove dust and debris before reinstallation |

| Verify refrigerant lines | Look for kinks or damage |

| Test run after install | Observe for leaks or unusual noises |

Regular maintenance and understanding of Kia Tuning concepts can help prevent issues during reinstallation. Proper reinstallation maintains efficiency and longevity of your ice cream machine.

The Role of Nozzles and Dispensing Valves

Ever wondered how ice cream smoothly shifts from the machine into your cone? Nozzles and dispensing valves play an essential role in this process. They control the flow, guaranteeing each scoop is perfect. To optimize this, consider these key points: 1. Properly calibrated nozzles maintain consistent portion sizes, reducing waste. 2. Different nozzle sizes allow for a variety of ice cream flavor options, enhancing menu diversity. 3. Well-maintained valves prevent leaks and guarantee a clean, efficient dispense. 4. Accurate control of flow boosts customer satisfaction by delivering smooth, uniform servings every time. Additionally, regular maintenance of these parts supports sensory processing and ensures the best customer experience.

Keeping the Evaporator Coils in Top Shape

Properly functioning evaporator coils are essential for maintaining the quality and efficiency of your ice cream machine. Regular evaporator cleaning prevents frost buildup and ensures peak heat transfer, which keeps your product consistent. Make sure to remove any ice or debris from the coils to avoid strain on the compressor and to improve freezing times. Additionally, check coil insulation regularly; damaged or worn insulation can lead to heat transfer issues, reducing efficiency and increasing energy costs. Proper insulation also prevents moisture buildup around the coils, which can cause corrosion. By keeping your evaporator coils clean and well-insulated, you extend their lifespan, improve machine performance, and maintain the quality of your ice cream. Regular maintenance is a small investment that saves you money and headaches down the line. Monitoring air quality can also help identify early signs of issues with your equipment, ensuring prompt maintenance and optimal operation.

The Significance of the Mixing Auger and Agitator Parts

The mixing auger and agitator parts play a crucial role in guaranteeing your ice cream machine produces smooth, consistent products. Without them, your ice cream could be uneven or too soft. Here’s why they matter:

- The mixing auger moves ingredients evenly, preventing pockets of air or ice crystals.

- The agitator parts help incorporate air, creating a creamy, desirable texture.

- Proper functioning ensures your product maintains the right consistency during operation.

- Regular inspection of these parts prevents motor strain and extends your machine’s lifespan.

- Maintaining these components also supports the overall emotional connection customers have with your brand by delivering high-quality, satisfying treats.

Recognizing and Fixing Electrical Components

Since the mechanical parts like the auger and agitator rely on electrical components to function correctly, recognizing and maintaining these parts is vital for your ice cream machine’s performance. Start by checking electrical connections regularly for loose wires or corrosion. Faulty sensors can cause issues with temperature calibration, leading to inconsistent product quality. If your machine isn’t maintaining the right temperature, it’s often an electrical problem that can be fixed with simple repairs or replacements. Proper electrical maintenance not only guarantees peak operation but also improves customer service by providing consistently high-quality ice cream. Familiarize yourself with your machine’s electrical schematics, and address issues promptly to prevent costly repairs. Regularly inspecting electrical connections and components can help identify potential problems before they cause downtime. Staying proactive keeps your machine running smoothly and keeps your customers happy.

Maintaining the Condenser and Refrigeration System

Regularly maintaining the condenser and refrigeration system is essential to keep your ice cream machine running efficiently. Proper cleaning procedures help remove dust and debris that can hinder heat transfer, improving energy efficiency. To do this effectively:

Regular condenser maintenance ensures efficient operation and extends your ice cream machine’s lifespan.

- Turn off the machine and unplug it.

- Remove the condenser cover to access coils.

- Use a soft brush or compressed air to clear dirt and dust.

- Wipe down surfaces with a damp cloth and ensure all components are dry before reassembling.

These steps prevent strain on the compressor, reduce energy costs, and extend the lifespan of your equipment. Regular maintenance guarantees ideal performance, keeps temperatures consistent, and saves you money in the long run. Prioritize cleaning procedures to maintain peak energy efficiency.

Frequently Asked Questions

How Often Should Ice Cream Machine Parts Be Inspected?

You should inspect your ice cream machine parts regularly, ideally weekly, to guarantee optimal performance. Check the frozen storage components for signs of ice buildup and verify ingredient freshness to prevent spoilage. Regular inspections help you spot issues early, maintaining quality and safety. Keeping everything clean and functioning properly not only extends the machine’s lifespan but also guarantees your customers get the best-tasting, fresh ice cream every time.

What Are Common Signs of a Failing Sealing System?

You should watch for failure indicators in your sealing system, as they signal potential issues. Common signs include leaks, unusual noises, or a decline in product quality. If the sealing system isn’t tight, it can cause contamination or spoilage. Regularly inspecting for cracks, wear, or looseness helps prevent costly breakdowns, ensuring your machine operates smoothly. Address failure indicators promptly to maintain ideal performance and customer satisfaction.

Can DIY Repairs Extend the Lifespan of Machine Components?

Did you know that proper DIY maintenance can extend your ice cream machine’s lifespan by up to 30%? By performing routine checks and repairs yourself, you can catch issues early and reduce downtime. Keep spare parts availability in mind, so you’re prepared to fix minor problems quickly. This proactive approach not only saves money but also ensures your machine runs smoothly longer, making it a smart move for your business.

Which Parts Are Most Vulnerable to Wear and Tear?

You should focus on parts most vulnerable to wear and tear, like the compressor, auger, and seals. Regular lubrication maintenance is vital to prevent damage, and adhering to replacement schedules helps extend their lifespan. By staying proactive with inspections and timely replacements, you reduce downtime and costly repairs. Keep a close eye on these components, and your machine will stay in top shape, ensuring consistent performance and customer satisfaction.

How Does Improper Cleaning Affect Machine Performance?

Improper cleaning is like ignoring a leaky faucet; it damages your machine’s performance. When you skip or rush cleaning protocols, residue builds up, clogging parts and causing inconsistent ice cream texture. This can throw off your machine calibration, leading to longer freezes or breakdowns. Regular, thorough cleaning guarantees your machine runs smoothly, keeps parts in top shape, and guarantees your ice cream is perfect every time.

Conclusion

Keeping your ice cream machine parts in top shape isn’t just about maintenance — it’s about ensuring your customers keep coming back. Sometimes, a small seal or gasket failure can cause unexpected downtime, reminding you that even the tiniest component plays a big role. By staying attentive and proactive, you turn routine repairs into opportunities for growth. After all, it’s these small details that often turn a good business into a great one.