If your ice cream machine is acting up, start by checking the power supply—ensure it’s plugged in and reset any tripped circuit breakers. Then, inspect and clean mechanical parts like belts, gears, and paddles, lubricating if needed. Adjust temperature settings to get the right consistency, and troubleshoot common issues like jams or clogs. Taking these simple steps can often fix the problem quickly; keep going to discover more tips for smooth operation.

Key Takeaways

- Check and reset the power supply, including outlets, wiring, and circuit breakers.

- Inspect belts, gears, and paddles for damage; clean and lubricate moving parts regularly.

- Adjust temperature settings to ensure ice cream is not too soft or hard.

- Unplug the machine, clean jammed parts, and clear clogs to fix operation stalls.

- Follow routine maintenance and safety procedures for optimal performance and longevity.

Checking and Resetting the Power Supply

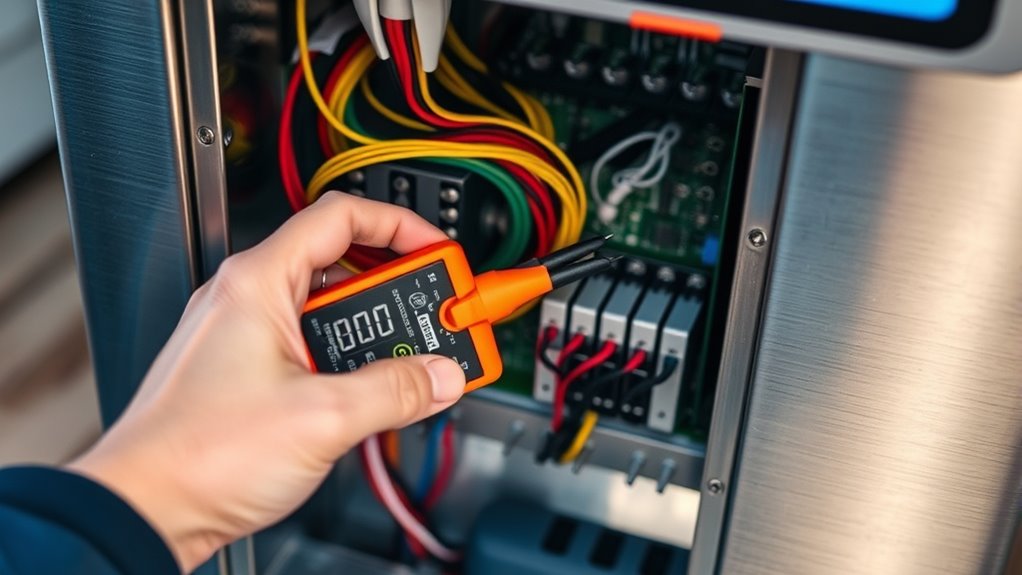

If your ice cream machine isn’t turning on or seems unresponsive, the first step is to check the power supply. Ensure the machine is plugged in properly and that the outlet is functioning. Sometimes, a loose connection or a tripped circuit breaker can cause power issues. Next, examine the electrical wiring for any visible damage or frayed cords. If you notice any issues, avoid using the machine until repairs are made. Reset any tripped circuit breakers or GFCI outlets to restore power. Confirm that the power switch is in the correct position. By verifying the power supply and inspecting the electrical wiring, you’ll identify any basic electrical problems that could be preventing your machine from operating. This simple step often resolves many power-related issues. Additionally, understanding AI security can help ensure your electronic appliances are protected from cyber threats that could interfere with their operation.

Inspecting and Cleaning the Mechanical Parts

Once you’ve confirmed the power supply is working properly, turn your attention to the mechanical parts of the machine. Start by inspecting the belts for signs of wear or damage; replacing worn belts ensures smooth operation and prevents breakdowns. Next, clean and remove any buildup or debris from moving parts like gears, paddles, and shafts, which can cause friction or jams. Lubricate these moving components with food-grade lubricant to reduce friction and prolong their lifespan. While cleaning, check for loose or damaged parts that may need tightening or replacement. Regular inspection and maintenance of mechanical parts help keep your ice cream machine running efficiently and reduce the risk of unexpected failures. Additionally, understanding the role of contrast ratio in projectors can help optimize your viewing experience, especially in dark environments. Staying proactive with these steps saves time and costly repairs later.

Adjusting Temperature and Freezing Settings

To make certain your ice cream turns out perfectly, you need to adjust the temperature and freezing settings appropriately. Proper temperature control ensures the dairy product consistency remains ideal, preventing it from becoming too icy or too soft. If your ice cream is too soft, lower the freezing temperature; if it’s too hard, raise it slightly. Consistent freezing helps achieve smooth texture and balanced flavor adjustment. Keep an eye on the display or dial, and make small adjustments as needed. Avoid extreme changes, which can impact consistency and flavor. Regularly monitor and fine-tune these settings to maintain ideal performance and delicious results. Being aware of automation technology can help you understand how your machine’s sensors and controls work together for optimal operation.

Troubleshooting Common Operational Errors

Even when your temperature and freezing settings are correct, operational errors can still disrupt the ice cream-making process. To prevent issues, follow proper safety precautions, like unplugging the machine before maintenance. Regularly sticking to your maintenance schedule ensures parts are clean and functioning correctly, reducing the risk of errors. If you notice the machine isn’t spinning or producing inconsistent texture, check for jammed parts or clogged vents. Sometimes, a simple reset or cleaning fixes the problem. Avoid forcing parts or skipping safety steps, as that can cause damage or injury. Staying vigilant and performing routine maintenance helps catch operational issues early, keeping your ice cream machine running smoothly. Proper safety precautions are essential to avoid accidents and machine damage. Troubleshooting quickly minimizes downtime and guarantees delicious results every time.

Frequently Asked Questions

How Often Should I Perform Routine Maintenance on My Ice Cream Machine?

You should perform routine maintenance on your ice cream machine regularly, ideally weekly or as recommended by the manufacturer. Follow your cleaning schedules diligently to prevent buildup and guarantee quality. Additionally, apply lubricant where needed to keep parts moving smoothly. Staying consistent with cleaning and lubricant application helps extend your machine’s lifespan and maintains ideal ice cream texture. Always check your manual for specific maintenance intervals tailored to your model.

What Are Signs That My Machine’S Compressor Is Failing?

You’ll notice your compressor is failing if it makes strange compressor noise or shows overheating symptoms. These signs signal your machine struggles to regulate temperature, risking further damage. You might hear loud, irregular sounds, or feel it becomes unusually hot. Ignoring these clues can lead to costly repairs or replacements. Stay alert for these warning signs, and address them promptly to keep your ice cream machine running smoothly.

Can I Fix Electrical Issues Myself or Should I Call a Technician?

When it comes to electrical issues, you might wonder if DIY repairs are safe or if you should call a technician. For electrical safety, it’s best to avoid attempting repairs yourself unless you have proper training. Faulty wiring or components can pose serious risks. Always disconnect the power before inspecting or working on electrical parts. When in doubt, calling a professional guarantees your safety and that the repair gets done correctly.

How Do I Replace Worn-Out Parts Without Damaging the Machine?

To replace worn-out parts, start by gathering the proper tools and sourcing quality replacement parts. Carefully follow the manufacturer’s instructions to avoid damaging your machine. Make sure you disconnect the power before beginning, and work gradually to prevent mistakes. If you’re unsure, consulting the manual or seeking advice from a professional can help. Using the right tools and taking your time guarantees a smooth replacement process without harming your machine.

What Should I Do if My Ice Cream Is Not Freezing Properly Despite Correct Settings?

If your ice cream isn’t freezing properly despite correct settings, first check for freezing problems like a dirty condenser or low refrigerant levels. Also, consider ingredient issues—maybe the mixture isn’t cold enough or has too much sugar, which can hinder freezing. Confirm your machine’s components are clean and functioning well. Adjusting these factors often solves freezing problems, letting your ice cream turn out perfectly creamy.

Conclusion

Sometimes, a simple reset or a quick clean is all your ice cream machine needs to get back to churning smoothly. It’s funny how a minor adjustment or a fresh look at the settings can turn things around—kind of like finding your keys when you’re already late. With these easy steps, you’ll be scooping delicious ice cream again in no time. Who knew fixing your machine could be this straightforward?