Choosing used machines can save you money upfront, but you might face higher maintenance, repairs, and limited warranties later. New equipment costs more initially but often comes with better support, warranties, and fewer hidden issues. Long-term, used machines depreciate less and can maintain value, but repair costs may add up. If you want to weigh these factors carefully and discover how to maximize your savings, keep exploring the details below.

Key Takeaways

- Used machines offer lower upfront costs, freeing budget for maintenance, upgrades, or better financing options.

- New equipment includes latest features and warranties, reducing repair costs but increasing initial investment.

- Used machines may incur higher repair and maintenance expenses over time, potentially offsetting initial savings.

- Resale value and depreciation are typically better with used equipment, enhancing long-term investment returns.

- Consider long-term costs, support, and reliability when choosing to maximize savings and operational efficiency.

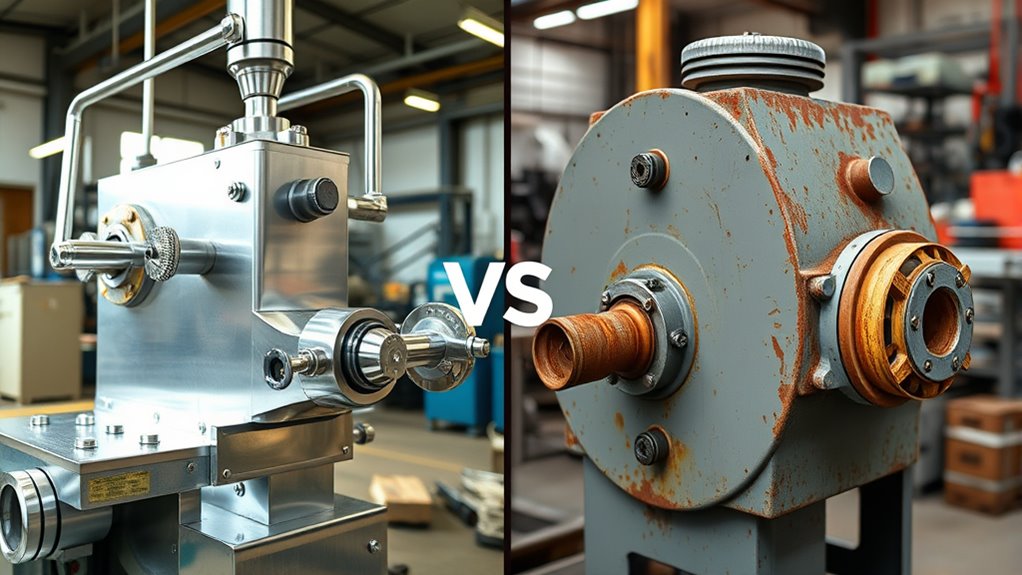

The Initial Cost Difference Between Used and New Machines

When considering the initial purchase, used machines generally cost considerably less than new ones. Your budget stretches further, allowing you to acquire quality equipment at a fraction of the price. Brand reputation plays a key role here; reputable brands tend to hold their value and offer reliable used options, giving you confidence in your investment. Additionally, financing options make purchasing used equipment more accessible, often offering lower interest rates or flexible payment plans. This can help you manage cash flow more effectively. While new machines come with the latest features, their higher price tag can be a barrier. By choosing used, you save money upfront and can allocate funds toward maintenance or upgrades down the line. Recognizing the comparative advantage of used equipment can further inform your purchasing decision, ensuring you maximize value for your investment.

Hidden Expenses of Buying Used Equipment

When buying used equipment, you might face unexpected costs like ongoing maintenance and repairs. Warranty limitations could leave you paying for repairs out of pocket, and hidden defects or damage may surface later, adding to your expenses. These hidden costs can quickly outweigh the initial savings, so it’s important to contemplate them before making a purchase. Additionally, security vulnerabilities in used machines may pose risks if not properly assessed and managed.

Maintenance and Repairs

One of the most significant hidden costs of buying used equipment is the potential for ongoing maintenance and repair expenses that can quickly add up. When doing a cost comparison, consider that older machines often require more frequent repairs, which can reduce their effective equipment lifespan. This can lead to unexpected expenses that eat into your savings. To better understand these costs, keep in mind:

- Repairs may be more frequent and costly, impacting your budget.

- Parts availability might be limited, increasing repair time and expenses.

- Regular maintenance might be neglected in older equipment, accelerating wear and tear.

- Additionally, secondhand items may lack warranties, increasing the risk of costly repairs after purchase.

While used equipment may initially seem cheaper, these hidden costs could diminish any savings, especially when factoring in the true equipment lifespan and ongoing upkeep.

Warranty Limitations

While older equipment might save you money upfront, warranty limitations can quickly erode those savings. Used machines often come with limited or no extended warranty, meaning you’ll pay out of pocket for repairs beyond the basic service coverage. This can lead to unexpected expenses if the machine breaks down after the warranty expires. Additionally, color accuracy and other performance features may not meet your expectations without proper calibration or upgrades.

Be sure to evaluate the warranty terms carefully. Sometimes, investing in an extended warranty can help protect your savings, but always weigh the cost against potential repairs.

Hidden Defects or Damage

Buying used equipment can seem like a cost-effective choice, but hidden defects or damage often lurk beneath the surface. Surface damage, such as scratches or dents, and cosmetic flaws might seem minor, but they can hide serious issues. These hidden problems can lead to costly repairs and downtime later on. Be cautious and look beyond what’s visible. Consider these points:

- Surface damage may disguise internal component wear or corrosion.

- Cosmetic flaws don’t guarantee the machine’s structural integrity.

- Visible damage can indicate rough handling or underlying mechanical issues.

- Utilizing proper inspection techniques, such as examining the equipment’s operating history and performing thorough testing, can help reveal potential hidden defects.

Always inspect thoroughly and ask for detailed maintenance records. Remember, what appears minor on the surface could hide significant damage that affects performance and longevity.

Depreciation Rates and Their Impact on Value

Depreciation rates considerably influence the resale value of machines, impacting your long-term investment decisions. When you buy new, depreciation occurs quickly, often reducing the machine’s value by 20-30% within the first year. This decline affects your ability to recoup costs if you sell later. Conversely, used machines typically have lower depreciation rates, maintaining their value better over time. Your lease terms and financing options also play a role—longer lease terms can spread costs but may accelerate depreciation effects. Choosing between new and used involves understanding how depreciation impacts future resale value, cash flow, and overall costs. By considering depreciation rates, you can better plan your investments, ensuring you maximize savings and minimize losses over the machine’s lifespan. Additionally, understanding efficiency ratings can help you select models that retain value longer and perform better over time.

Maintenance and Repair Costs Over Time

Understanding how maintenance and repair costs evolve over time is key to evaluating the true long-term expense of your machines. As your equipment ages, you’ll likely face increased parts replacement, which raises overall costs. Additionally, downtime costs spike when machines break down unexpectedly, disrupting your operations and reducing productivity. To manage these expenses, keep in mind: 1. Older machines often require more frequent parts replacement, increasing maintenance costs. 2. Downtime costs can surpass repair expenses if machine failures are frequent or prolonged. 3. Regular inspections and preventative maintenance help minimize unexpected repairs and downtime. Moreover, choosing vetted products and following manufacturer guidelines can extend machine lifespan and reduce unforeseen expenses.

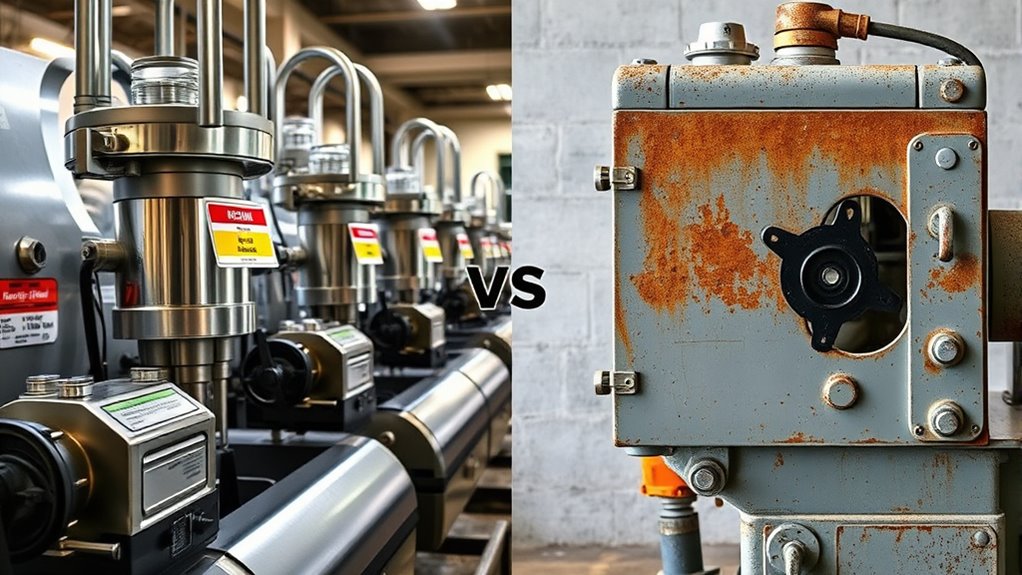

Warranty and Support Considerations

Warranty and support plans play a crucial role in managing your long-term costs and guaranteeing smooth operations. When choosing between used and new machines, consider the quality of after sales service and technical support offered. New machines typically include extensive warranties that cover repairs and parts, giving you peace of mind. They also often come with dedicated technical support that helps resolve issues quickly, minimizing downtime. Used machines may have limited or no warranty, making you more reliant on external repair services, which can increase costs and delays. Make certain you understand the support options available, as good after sales service can save you money and hassle over time. Ultimately, a strong warranty and support plan can make a significant difference in your overall investment. Additionally, understanding the world of Bollywood can offer insights into popular trends and entertainment options that align with your needs.

Resale Value and Long-Term Investment

When evaluating your options, consider how well a machine will retain its value over time. Resale value impacts your long-term investment, especially if you plan to upgrade later. Used machines often depreciate less initially, making them potentially better investments. Keep these points in mind: 1. Shorter lease terms can help you upgrade sooner, preserving resale value. 2. Favor machines with a reputation for durability to ensure higher resale prices. 3. Explore flexible financing options that improve your ability to maintain or upgrade equipment efficiently. Additionally, choosing machines from trusted brands with air-purifying qualities can enhance their long-term appeal and resale potential.

Making the Smarter Choice for Your Budget

Choosing between used and new machines ultimately depends on your budget and financial goals. To make a smarter choice, consider factors like brand reputation and available financing options. A reputable brand often means better durability and support, which could save you money long-term. Meanwhile, flexible financing plans might make a new machine more accessible now, even if it stretches your budget. Here’s a quick comparison:

| Factor | Used Machines | New Machines |

|---|---|---|

| Brand Reputation | Varies; research is essential | Generally higher, trusted brands |

| Cost | Lower upfront, possibly higher maintenance | Higher upfront, potential discounts |

| Financing Options | Limited, may require cash upfront | More flexible, leasing, or loan options |

| Long-term Savings | Possibly higher due to repairs | Better warranty and lower maintenance costs |

Choose wisely to align your investment with your financial goals. For example, understanding brand reputation can help ensure you’re making a durable and reliable purchase.

Frequently Asked Questions

How Does the Quality of Used Machines Compare to New Ones?

You might wonder how used machines compare in quality to new ones. Generally, used equipment can offer good value, but machine longevity and equipment reliability vary based on previous usage and maintenance. While some used machines still perform well and last years, others may break down sooner. Carefully inspecting and choosing reputable sellers helps make certain you get a used machine that meets your standards for durability and reliable performance.

Are There Tax Advantages When Purchasing New Versus Used Equipment?

You might think tax advantages are a minor detail, but they can be a game-changer. When you purchase new equipment, you open incredible tax incentives and depreciation benefits that can slash your taxable income dramatically. Used machines, while cheaper upfront, often don’t qualify for the same level of depreciation perks. So, if maximizing savings matters, buying new could give you a significant tax edge you don’t want to miss.

What Factors Influence the Lifespan of Used Versus New Machinery?

You should consider many factors influencing machine lifespan, like maintenance costs and warranty coverage. New machinery often comes with a warranty, reducing repair expenses early on, which can extend its useful life. Used machines may need more frequent maintenance, potentially decreasing their lifespan. Your decision depends on how well you maintain equipment and whether warranty support is essential, impacting how long your machinery stays productive and cost-effective.

How Quickly Do Used Machines Typically Depreciate?

Imagine your used machine as a vintage car—its resale value drops quickly at first, then stabilizes. Typically, used machines depreciate at a faster rate initially, often losing 20-30% of their value in the first year. After that, the depreciation rate slows down. Knowing this helps you plan resale timing; early depreciation impacts resale value most, so consider how fast you need to recover your investment.

What Are the Risks of Hidden Damages in Used Equipment?

Hidden damages in used equipment can pose serious risks, leading to unexpected repair costs that eat into your savings. You might face inspection challenges, making it hard to identify issues before purchase. These damages can cause breakdowns and reduce equipment lifespan, so it’s vital to thoroughly inspect used machines and consider potential repair costs upfront. Doing so helps you avoid costly surprises and guarantees you make a smarter investment.

Conclusion

Ultimately, choosing between used and new machines isn’t just about the upfront savings. While used equipment might seem like a quick win, the subtle costs and potential compromises could quietly add up over time. On the other hand, investing in new machines offers peace of mind and better support, helping you avoid unexpected surprises. Weigh your options carefully—sometimes, spending a little more now can gently steer you toward smoother, more reliable operations down the road.